Secure Remote Printing of Spare Parts for the Oil and Gas Industry: Assembrix, HP, Sparely, and Korall Engineering Complete Global Series

A milestone in secure, distributed 3D printing for the global energy sector TEL AVIV, Israel, PALO ALTO, Calif., APELDOORN, Netherlands and BERGEN, Norway, Nov. 17, 2025 /PRNewswire/ -- Assembrix Ltd., HP, Sparely, and Korall Engineering AS have completed a series of secure remote additive manufacturing (AM) operations across multiple sites worldwide to produce certified spare parts for the oil and gas industry. The collaboration demonstrates how distributed manufacturing enables secure, efficient, and scalable on-demand production of critical components near the point of need. For an industry reliant on continuity and fast response, this milestone shows that secure digital production can enhance efficiency, lower costs, and strengthen supply-chain resilience.Innovation and Scalability: Global Secure Printing SeriesOver the course of the series, certified polymer spare parts were printed at several HP partner sites using HP Multi Jet Fusion (MJF) systems integrated with the Assembrix software platform. Printed parts included a series of polymer valve handwheels, designed by Korall Engineering for oil and gas service, enabling manual operation of non-critical valves on ships and offshore platforms. Korall, in collaboration with ...Full story available on Benzinga.com

This achievement marks a significant milestone in distributed manufacturing, showcasing how digital production can revolutionize the supply chain for an industry heavily reliant on continuous operation and rapid response times. The series highlighted the potential for enhanced efficiency, reduced costs, and increased supply-chain resilience through secure, on-demand manufacturing.

The core of the project involved printing certified polymer spare parts at various HP partner locations around the world. These locations utilized HP's Multi Jet Fusion (MJF) systems, a cutting-edge 3D printing technology, integrated with the secure Assembrix software platform. This integration ensured the integrity and confidentiality of the designs throughout the entire printing process.

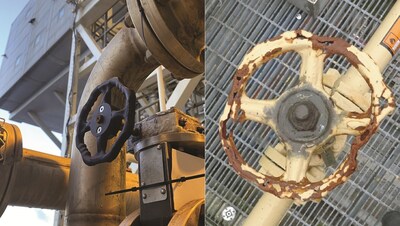

A key example of the parts produced during this series was a set of polymer valve handwheels. These handwheels, designed by Korall Engineering specifically for oil and gas service applications, are essential for the manual operation of non-critical valves found on ships and offshore platforms. The successful printing of these parts demonstrates the capability to produce functional, certified components remotely, addressing a critical need within the industry.

The collaboration between Assembrix, HP, Sparely, and Korall Engineering underscores the transformative potential of additive manufacturing in the oil and gas sector. By enabling secure and distributed production, this innovative approach promises to streamline operations, minimize downtime, and create a more agile and responsive supply chain for the global energy industry. Further details about this groundbreaking series are available on Benzinga.com.